- The Kiln is normally rotating at 3.0 to 5.5 RPM and at both the ends, at inlet and outlet, the Kiln subject to the vacuum. If proper sealing is not provided, the false air enters through the ends of the Kiln at inlet as well as outlet, and.

- The false air, which enters at INLET, reduces the capacity of fans, as this air is false air and not participating in combustion of coal, which is taking place in the burning zone. So, it directly reduces the output of the Kiln to the extend of false air.

-

The false air at the OUTLET is directly affecting the heat efficiency of the cooler. The false air, which enters at the outlet, is at an ambient air temperature between 20 to 45oC, which replaces the secondary air from the cooler, ranging from 1100 to 1250oC. So, directly affecting the heat loss.

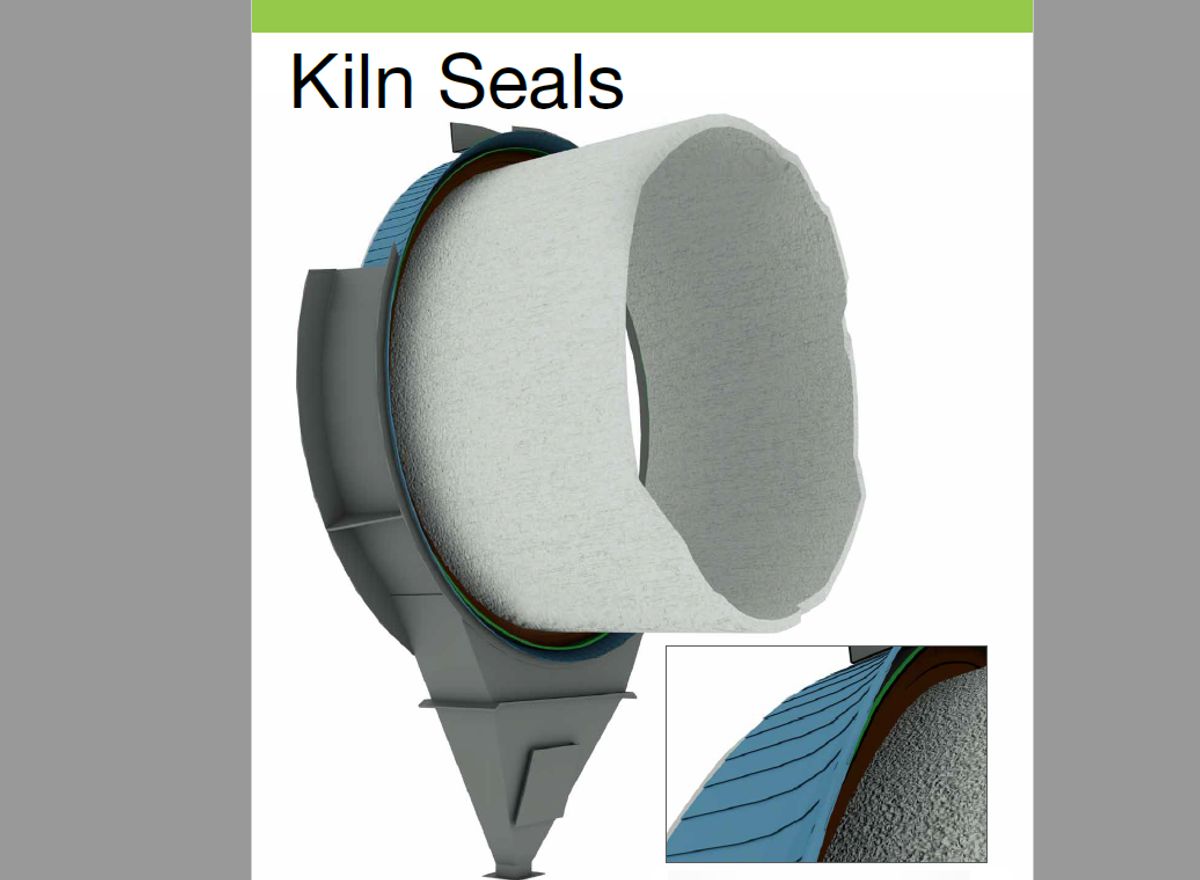

Normally the seals are available in ‘Inverted Leaves Spring Loaded Stainless Steel’ or ‘Graphite Blocks’. The Inverted Leaves Spring Loaded Stainless Steel Seals are having limitation because of lamination and from every joints the false air is entering into the Kiln and in the Graphite Block Seals, there is perfect sealing, but subject to the wear and tear caused by the clinker particles coming from the Kiln Hood occasionally because of pressurization.

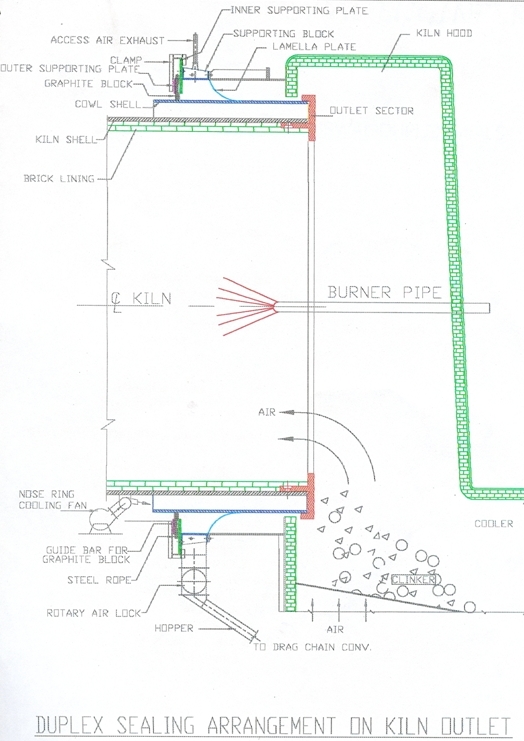

To overcome these problems, OSWAL has specially developed DUPLEX Seals in two stages. In first stage, Inverted Leaves Spring Loaded Stainless Steel Seal arrests the clinker particles in case of pressurization and in second stage, the seals are of Graphite Blocks. Since the clinker particles are arrested by the Inverted Leaves Spring Loaded Stainless Steel Seal, the Graphite Block Seal runs trouble free without any wear because of the clinker particles. In between the Inverted Leaves Spring Loaded Stainless Steel and the Graphite Block Seals, the sealing air is supplied, which is interlocked with the air chamber temperature. If the temperature goes above 400oC, then the air from the nose cooling fan through butterfly damper will enter and cool the air of the chamber between these two Seals and will pass from the Chimney provided at the top, which is closed by a light weight flap.

With the application of these seals, approximate saving is from 4.5 to 6.0 K.Cal/Kg. of Clinker and if the condition of the existing seal is worst, then the saving will be more.

Apart from the above saving, these seals also avoid the formation of snowman in the Cooler and coating formation in the Kiln Inlet by avoiding condensation of hot meal due to in grace of cold air. It will also held in increasing the Kiln output to the tune of heat saved at Kiln Outlet and air saved at Kiln Inlet.