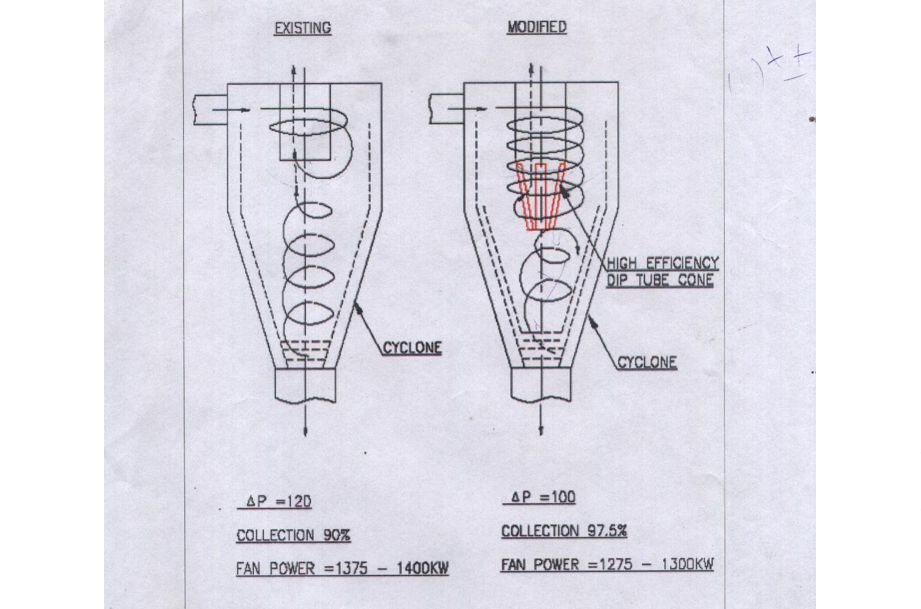

OSWAL MODIFICATION OF CYCLONE SEPARATOR

The Cyclone Separator is one of the simplest and most reliable equipment for separating the solid particles from the air. However, it is not the energy efficient. In the cyclone separator, dust ladden gas enters tangentially inside the cyclone, causing centrifugal force on dust particles. Due to sudden volume increase, the velocity of gas drops and dust particles are thrown away by

centrifugal force gained by the inlet gas velocity and the gases are sucked through the central tube..

Since the dip tubes are centrally located, the gas enters at randomly, causing the turbulence flow as well the lighter particles, which are not thrown upto the walls of cyclone, are caught by the exit flow gases and carried away by exit gases.

Due to the turbulence flow, pressure drop across the cyclone increases as well the power consumption of the fan.

Due to the entrapping of separated solid particles by the exit gases, the separation efficiency of the cyclone also drops.

To improve the cyclone efficiency, following modifications are required:

As in the cyclone separator, the separation takes place by centrifugal force and the centrifugal force is resultant of inlet velocity, so it is very important to maintain minimum velocity. At the same time, higher velocity results in higher-pressure drop, consumes more electrical powers. So, both the situations are not desirable and for both efficiency of cyclone for separation as well energy, the optimum design of inlet is desired.

To avoid turbulence flow to have smooth exit gas flow, dip tubes are so designed that smooth exist is followed after cyclonic effect. So, there is no extra pressure drops due to turbulence flow. Since the gas enters inside the cyclone, velocity of gases gradually drops, then it moves circumferentially and the quantity of gases also drops when the gases travel from top towards the bottom of cyclone. To meet the actual gas velocity condition as well as quantity of gases, the dip tubes are designed in such a way that the exit gas velocity is maintained circumferentially as well as axially

In the cyclone, gases move upto the bottom of the conical portion.Though the velocity and quantity is very low, but still sufficient to carry back the separated solid particles upward in counter flow of the gases, which again reduces the separation efficiency. So, the bottom of cone is so designed, the velocity of gases are dropped to the minimum level and not capable of carrying back the finer particle of material collected and also having the blind bottom of central tube, which prevent counter current flow of gases through dip tubes. of gases, the dip tubes are designed in such a way that the exit gas velocity is maintained circumferentially as well as axially

The material collected in the cyclone is discharged through rotary air lock or flap valves. Normally rotary air lock and flap valves are designed for the convenience of maintenance, but without giving importance to the cost of operation. If suitably designed high efficiency rotary air locks are installed, which takes care for trouble free running and preventing the substantial quantity of false air & re-circulation of material, which ultimately results in lower power consumption, better performance of cyclone and lower wear and tear on cyclone internal parts as well as suction fan and ductings.

Looking to the above limitations of cyclone separator, the team of OSWAL ENGINEERS with the guidance of eminent professor of Indian Institute of Technology, we have designed and developed new cyclone, which take care of inlet velocity, smooth exit of gases through modified central tube and improved bottom of cyclone equipped with high efficiency rotary air lock of gases, the dip tubes are designed in such a way that the exit gas velocity is maintained circumferentially as well as axially

1. Across the cyclone reduces by 15 to 25% 2. The energy saving of the suction fan is approximately by 5-10%. 3. Separation efficiency improves upto 95-99%.

All types of cyclones provided for material collection with raw mill, cement mill, coal mill, pre-collector before separator, dust collector and all other application of cyclones.