Automatic samplers of coal, solid fuels and bulk materials

Collection of standard samples from belt conveyors, trucks and railway wagons

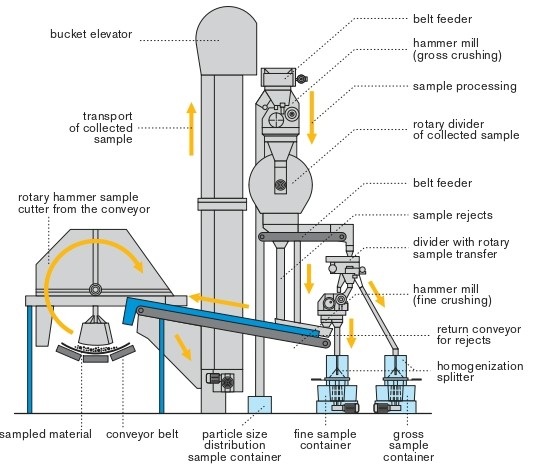

The industrial sampling unit is fully automated device for the regular collection and processing of samples in accordance with standards for solid fuel sampling. The device retrieves samples from belt conveyors or transfer points even in case of high transportation speed. The unit for sample collection from trucks or railroad wagons ensures smooth operation by the method of immersion of rotating auger. The automatic samplers are certified to process wide range of materials starting from fine dust up to coarse granularity and ensure maximum representativeness of sampling and high efficiency thanks to reliable and quick sample processing.

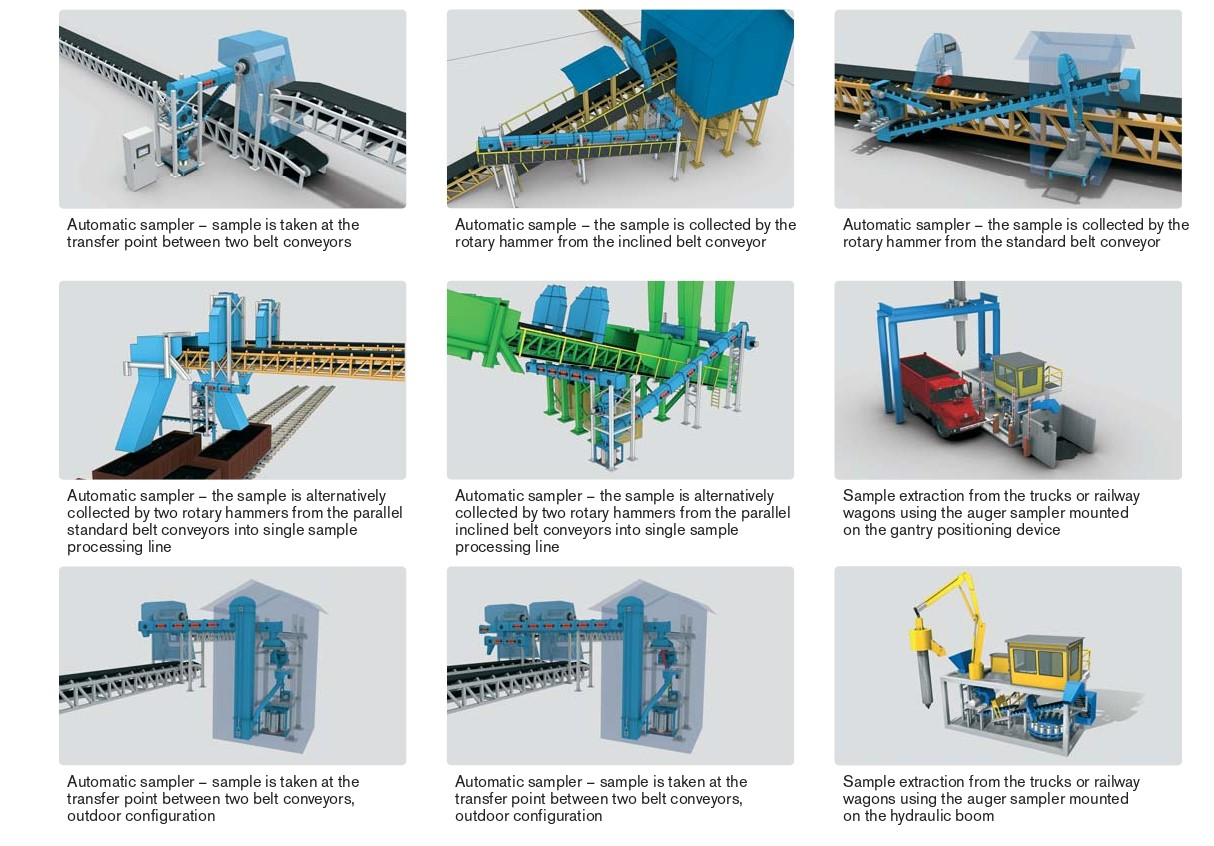

Most common sampler configurations:

The

rotary hammer sample cutter is attached to the belt conveyor frame. According to

the requirements of the relevant standards, the rotary hammer cuts the full crosssection

of the material stream on the main conveyor at constant speed. In each

sampling cycle, one sample increment is taken, delivered to the belt feeder and

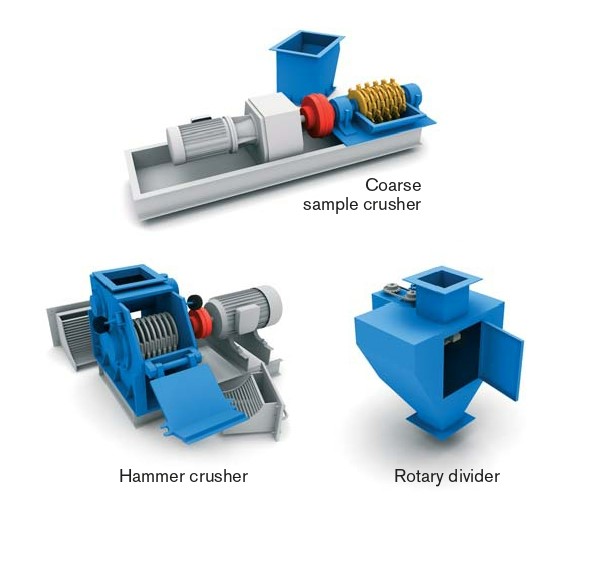

evenly dosed for coarse crushing to the 10 mm granularity. The sample is further

divided using the programmable divider and either stored to the sample

container or further processed by fine crushing. The unused material is returned

to the main conveyor. If required by the application, the sample processing line

can be equipped by on-line analyzer, collection of particle size distribution

sample, homogenization buffer for gross sample or sample splitter. An automatic

carousel can be used to collect samples separately into multiple containers.

Rapid analysis of sample

The sampler can be equipped by the unit for rapid sample analysis which is installed on the feeding or reject conveyor. The unit evaluates ash content, moisture and calorific value.

Work safety

The automatic sampler is thoroughly secured to prevent damages. In case that the sample cutter does not reach its home position within required time, the main conveyor is stopped to prevent conveyor overload or sampler destruction.

Sample representativeness

Primary sample increments are collected on timer basis. According to the information of batch size the control system chooses the optimal frequency of primary samples to achieve required amount of final sample for laboratory analysis. The detectors ensure that the sample timers are running only in case that the main conveyor is in operation and there is sufficient material layer for sampling.

Storage of collected samples

Depending on the method of further processing, the material is taken either into a collecting vessel to perform the granulometry test, or proceeds through a system of hammer mills where it is crushed to a grain size of 0-3 mm. As per individual application requirements the samples are stored into containers after division. Before storing into containers the samples can be mixed and divided at the homogenization splitter, where equal parts of the same sample are stored into several containers. To store different samples separately into different containers there can be utilized the rotating carousel for sample separation according to further criteria. If the sampler is equipped for particle size distribution sampling, the primary samples taken from the main conveyor can be redirected immediately to the special container without further processing.

Control system, power feed and operation

The automatic sampler is powered from the control cabinet with power and control circuits. The cabinet is usually installed close to the sampler line. The cabinet door carries the control buttons with signaling and rugged easy-to-use industrial control screen. There it is possible to set the sampling parameters, timing of the sample collection, startup of individual devices, view alarms and faults, watch the operational status of each device, number of executed sample increments, sample increment timers, time until next increment, etc.

Integration with online mining quality control system

The control system of the automatic sampler can be integrated with superior SCADA system or mining quality control system as per customer requirement (ModBus, ProfiBus, Ethernet, etc.).

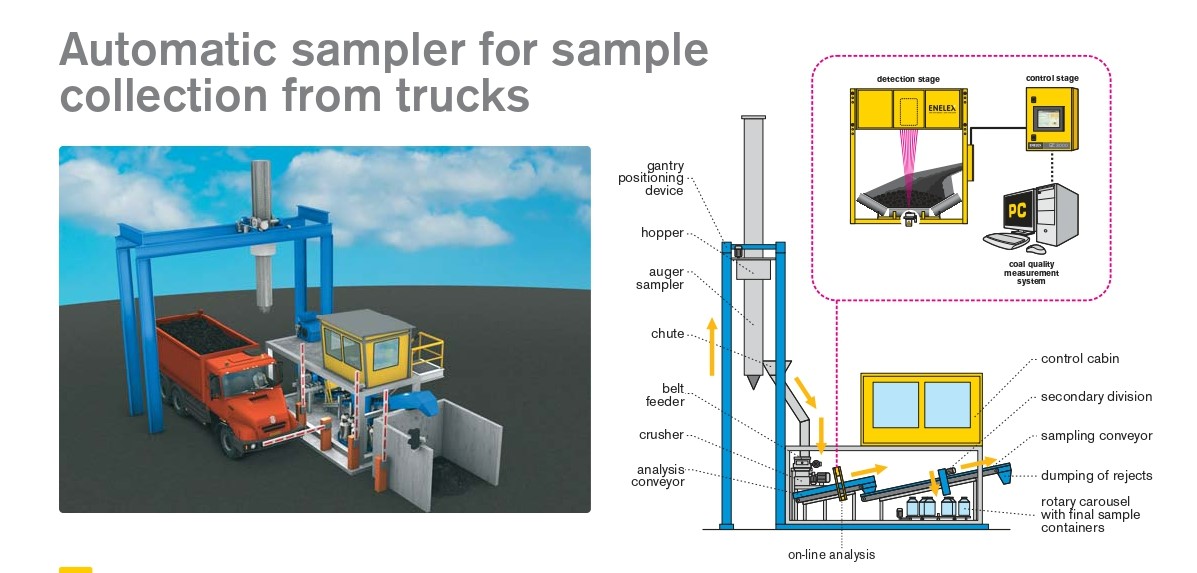

Basic description

The automatic truck sampler enables automated extraction of samples by the help of gantry positioning mechanism with the auger sampling device. The control system will choose the place of sampling on random basis to ensure representative sampling. Based on the operator confirmation the system will start an automatic sampling sequence and sample processing with no human influence. The sampler can be equipped by the rapid sample analysis implemented on the conveyor inside the sample processing line.

The auger sampling device is mounted on the positioning device which moves

the unit to the chosen position. The sample will be taken in accordance with

regulations from any place or depth of the dump truck bed. The auger will extract

the material from the truck while performing primary division. The needed part of

the sample is collected into the sample hopper and the rest is dropped back to

the truck. After the hopper is full, the sampler returns back to the home position

to discharge the sample into the chute of the processing line for further sample

processing.

From the chute the sample is transported to the crusher to be sized down to

10mm. The processing of the crushed sample continues onto the analysis

conveyor and then the sampling conveyor to be further divided by the secondary

sampling mechanism. The divided portion of the sample is stored into the

containers at the carousel, the remaining part is dumped outside the processing

line house

The sample containers are equipped by closing lids which are only opened in case of filling by the sample. The rotary carousel can handle up to 16 containers for sample storage so that the distinct final samples can be stored selectively according to different suppliers, freighters or other criteria. The sampler can be also equipped by automatic packing machine with indexing for long-term sample storage.

For the best achievable sample representativeness the place of sample extraction from the truck bed is chosen automatically on random basis. Based on the batch size information the system will determine the number of samples taken from the trucks in order to collect suitable amount of final sample for the laboratory analysis.

The sampler is controlled from the operator cabin. The process of sample extraction and processing is pre-programmed and fully automatic. Work of the operator is limited to start the automatic operation and supervision. Communication with the system is ensured by the rugged industrial-grade control panel where it is possible to monitor, change and setup all working parameters of the automatic system, e.g. the time of sample extraction, number of samples taken, statistics of samples taken for each supplier, status of individual devices etc. It is also possible to set the parameters of the sampling process and view the errors and alarm messages.

Advantages:

- Sample extraction from the full material depth

- Works with a range of coal qualities including wet or frozen material

- Short sample extraction cycle

- Integrates complete sample preparation procedure

- Environmental protection of the collected sample

- Simple operation and manipulation

- Automatic operation with one supervisor only